Wenatchee — The fruit growers’ world is both big and small. Their markets are national and global, yet their concerns and survival often hinge on local details. West Mathison knows this well. He is the fifth generation member of his clan to run the family business.

The Mathisons have been successful at both innovation and resilience, at balancing the grand scale and the local. They have been farming the hills around Wenatchee since West’s great great grandfather, a Scottish immigrant, arrived and homesteaded here in the 1890s. Their family created Stemilt Growers, one of the largest tree-fruit suppliers in the West. They ship fruit all over the country and produce more cherries than any other in the state: about 1.5 billion per year. They also ship 20 million boxes of apples, pears, apricots, peaches and nectarines. When it comes to tree fruit, they’re a veritable cornucopia.

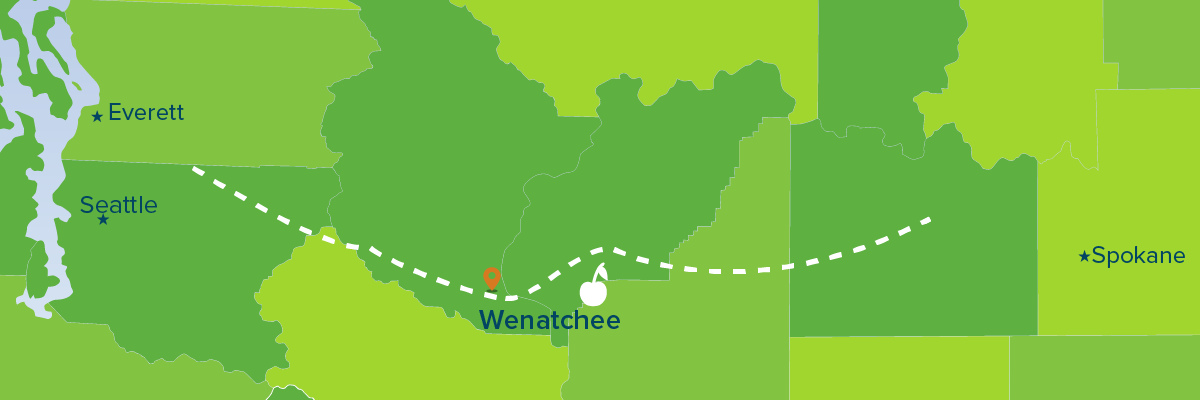

Following Highway 2 into Wenatchee, once dubbed “The Apple Capital of the World,”photographer Matt Mills McKnight and I wanted to learn how it was done and what the challenges of the tree-fruit business are.

For West Mathison, though, there’s never a sense of security. “There’s always an element of weakness,” he says of the orchard business. “You can have done everything right, and then there’s rain, hail, spring frost.”

It’s hard to believe that insecurity when you see Stemilt Hill and the surrounding basin with its vast orchards that climb the foothills as high as 4,000 feet. If you look up from the highest, you can see Mission Ridge ski area. Stemilt employs some 1,600 people year round, significantly more during harvest. It has a large, high-tech packing plant on the Columbia River and a wine-tasting room in Wenatchee’s restored historic district — yes they grow grapes on these hills and make their own wine, too.

If you imagine a plant filled with workers doing everything by hand, you’d have only half the picture at Stemilt’s fruit packing operations. Sophisticated machines now do a lot of the work, and they boggle the mind. For example, of those 1.5 billion cherries that pass through the warehouse to market each year, every single one is scanned by a computerized machine called a Cherry Vision 2. It photographs each cherry 36 times — nearly 28,000 images per second. From those scans, the computer figures out which are misshapen, bruised or otherwise flawed and kicks out the bad ones. Speed, precision, high-tech. This is not your father’s packing plant.

West is only part of the family picture. While he has been running the show since he took the company over in 2005 at age 28, his 64-year-old father, Kyle, is still involved in the farming side.

The two men could not be a greater contrast. West looks like he could be an exec at Amazon: He’s clean-shaven, wears a lanyard and a polo shirt. He’s excited talking about the production process and how the company is trying to create a sustainable workforce. He works in the office and delights in showing us his IT department.

Kyle Mathison stands for a portrait in the orchards where he has farmed apples and cherries for most of his life.

Dad Kyle, however, wears denim overalls and has a beard and a ponytail. Back in the day, he admits, he dropped out of college for an “easy Rider” phase, before finishing school at WSU with a degree in horticulture.

If West is great at the business, Kyle’s passion is making great fruit and getting his hands dirty. He farms by the moon cycles, he enthuses about flavors, and during our visit, before taking us into an organic orchard to see the picking up close, he shows us his favorite thing: rich compost brewing in great berms. His compost is made from a special recipe of Wenatchee yard waste, fruit culls and horse manure. The special compost helps the trees blossom, boosts the sugars and flavors, and promotes cell density, he enthuses. The macrocosm of the global market is partly conquerable due to the microcosmic bacteria in Kyle’s brew.

These alchemical details matter. Kyle knows the market wants flavor, firmness and freshness. You have to innovate at the level of finding and testing new formulas and breeds of fruit to meet the consumer’s standards.

While Kyle is working on flavor, West has to figure out how to get it to market in the best possible shape. It takes teamwork. That is reflected in the workforce as well. Latino workers dominate the plant and orchard workforce, and West and Kyle are very cognizant of their importance. “This is a people business,” West says. Of seasonal workers he says, “They are our guests.” Stemilt provides housing for some 1,2000 workers. There’s an on-site medical clinic with a doctor where they can get free healthcare, including physical therapy if needed. West says people want fruit that tastes great, yes, but they also “want altruism in their food.”

In addition to market fluctuations and bad weather, there are other challenges. Global competition, for one. China and South Korea are now in the global apple business competing with Washington growers. West says the European Union puts lots of money into agricultural R&D, pushing the technology forward. Some of their best equipment comes from places like Italy and The Netherlands.

It was a tech innovation that saved the Mathison’s family operation. In 1958, their entire harvest yielded only $88 dollars in total profit for the year on 100 tons of cherries. They figured out that part of the problem was their cherries looked terrible by the time they arrived in markets like New York. So, they innovated by shipping cherries in refrigerated railcars. Other innovations have followed, says Kyle, like being the first to sell cherries in plastic bags, or putting those little labels on apples. We had to “develop intelligence about the fruit,” says Kyle, and control how it reached market.

Some problems in the orchard are solved by old-school methods. During harvest, a falconer is brought in every morning, letting loose his trained raptors to clear the orchards of starlings and “red breasted starlings” — Kyle’s term for robins, which eat the cherries, though he says the birds do deserve a share.

West is the face of the company in the professional world. He’s on the Washington State Apple Commission, serves on the board of the Federal Reserve Bank of San Francisco, and sometimes goes to Olympia on behalf of the growers. He says he’s neither a Republican nor Democrat. He’s been frustrated with both parties and the current political dynamics. But, “I have faith in our country this politics will change. Right now it’s disheartening. We need immigration reform, and free and fair trade,” he reflects. He says he has hope things will improve.

Given what the Mathisons have accomplished in the Wenatchee hills for over 100 years, it’s no wonder that he takes the optimistic view.

Next: Day Four, a look at a landscape of power, water and inspiring big skies